ABSTRACT

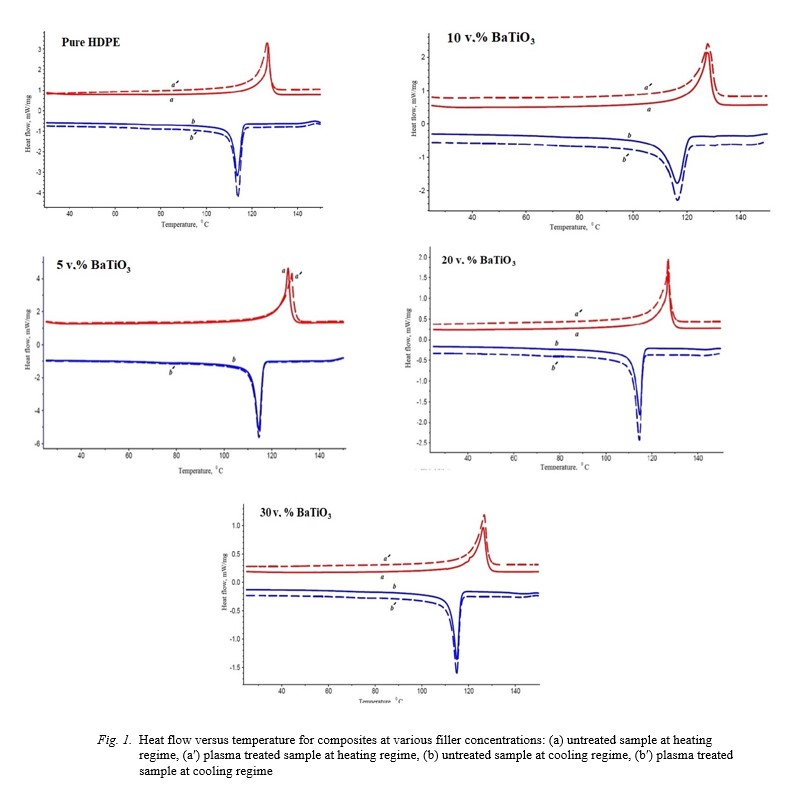

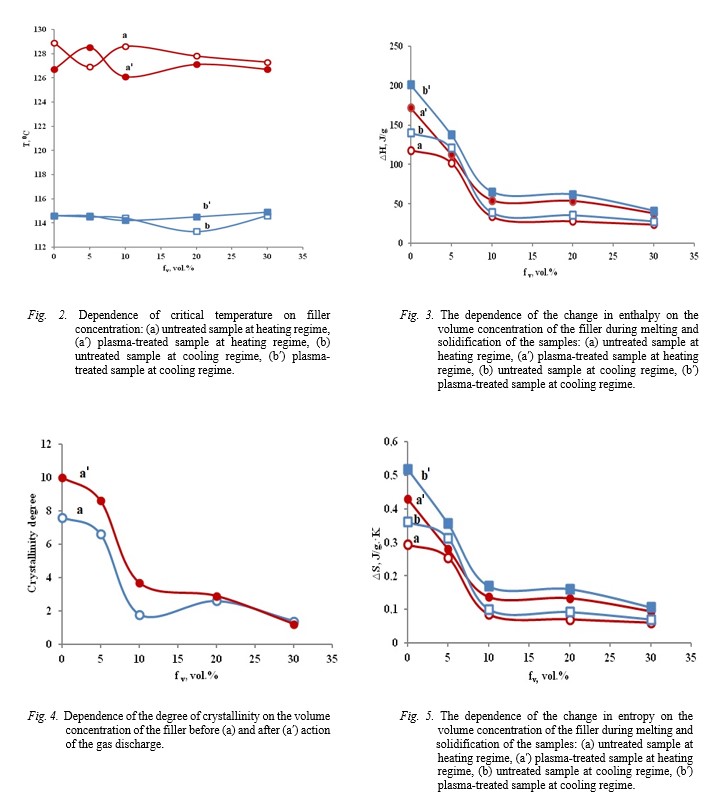

Composite films based on high-density polyethylene and barium titanate particles before and after treatment with a dielectric barrier gas discharge were studied by

differential scanning calorimetry. The values of critical temperatures, changes in entropy, enthalpy, and degree of crystallinity before and after the action of the gas

discharge are found. It is shown that the critical temperature after the action of a gas discharge decreases during heating, and increases during cooling, except for the

concentration of barium titanate particles of 5 vol. %. In addition, the change in entropy and enthalpy during discharge processing increases as well as the degree of

crystallinity. As the filler concentration increases, the change in enthalpy, entropy, and the degree of crystallinity decrease.

Keywords: barium titanate, high density polyethylene, dielectric barrier discharge plasma; enthalpy, entropy, crystallinity.

PACS: 77.84.Lf, 77.65.-j

DOI:-

Received: 08.02.2023

AUTHORS & AFFILIATIONS

Institute of Physics, Ministry of Science and Education of Azerbaijan 131, H. Javid ave., Baku, АZ 1143

E-mail: tdibragimov @mail.ru

Graphics and Images

Fig.1 Fig.2-3-4-5

|

REFERENCIES

[1] J.M. Grace and L.J. Gerenser. Plasma treatment of polymers, J. Dispersion Sci. Technol. 24 (2003) 305-341.

[2] S. Guimond and M.R. Wertheimer. Surface degradation and hydrophobic recovery of polyolefins treated by air corona and nitrogen atmospheric pressure glow discharge, J. Appl. Polym. Sci. 94 (3) (2004) 1291-1303.

[3] M. Pascual, R. Sanchis, L. Sanchez, D. García, and R. Balart. Surface modification of low density polyethylene (LDPE) film using corona discharge plasma for technological applications, Journal of Adhesion Science and Technology 22 (2008) 1425–1442.

[4] M.R. Sanchis, V. Blanes, M. Blanes, D. Garcia, R. Balart. Surface modification of low density polyethylene (LDPE) film by low pressure O2 plasma treatment, European Polymer Journal 42 (7) (2006), 1558-1568.

[5] L. Paralı. The electret effects of crystallized polymer–ferropiezoelectric composite under electric discharge plasma, Journal of Electrostatics, 76 (2015) 89-94.

[6] I. Novak, G.K. Elyashevichb, I. Chodak, A.S. Olifirenko, B.M. Steviar, M. Spírkova, N. Saprykina, E. Vlasova, A. Kleinova. Polymer matrix of polyethylene porous films functionalized by electrical discharge plasma, European Polymer Journal 44 (2008) 2702–2707.

[7] I. Novak, M. Steviar, A. Popelka, I. Chodak, J. Mosnacek, M. Spırkova, I. Janigova, A. Kleinova, J. Sedliacik, M. Slouf. Surface Modification of polyethylene by diffuse barrier discharge plasma. Polymer Engineering and Science (2012) 1-8.

[8] F. Arefi-Khonsaria, M. Tatouliana, F. Bretagnola, O. Bouloussab, F. Rondelez. Processing of polymers by plasma technologies. Surface & Coatings Technology 200 (2005) 14 – 20.

[9] W. Kun, L. Jian, R. Chunsheng, W. Dezhen, W. Younian. Surface modification of polyethylene (PE) films using dielectric barrier discharge plasma at atmospheric pressure. Plasma Science and Technology, 10 (4), (2008), 433-437.

[10] L. Parali, M.A. Kurbanov, A.A. Bayramov, F.N. Tatardar, I.S. Ramazanova & G.X. Huseynova. Effects of electric discharge plasma treatment on the thermal conductivity of polymer–metal nitride/carbide composites. Journal of Electronic Materials 44 (11) (2015) 4322–4333.

[11] M. Tahara, N.K. Cuong, Y. Nakashima. Improvement in adhesion of polyethylene by glow-discharge plasma. Surface and Coatings Technology 174–175 (2003) 826-830.

[12] R. Morent, N. De Geyter, T. Jacobs, S. Van Vlierberghe, P. Dubruel, C. Leys, E. Schacht. Plasma-polymerization of HMDSO using an atmospheric Pressure dielectric barrier discharge plasma process. Polym. 6 (2009) 537–542.

[13] H. Biederman D. Slavı́nská. Plasma polymer films and their future prospects. Surface and Coatings Technology. 125(1–3) (2000), 371-376.

[14] M.A. Kurbanov, V.A. Gol’dade, S.V. Zotov, I.S. Ramazanova, A.F. Nuraliev, F.F. Yakhyaev, U.V. Yusifova & B.G. Khudayarov. Generation of craze-formation centers in polymer films under the action of electric discharge plasma. Technical Physics 63 (2018) 965–969.

[15] A.I. Drachev, A.B. Gil’man. The synthesis of semiconducting polymers in a low-temperature plasma. Russian Journal of Physical Chemistry A, Focus on Chemistry 82 (2008) 1733–1741.

[16] F. Truica-Marasescu, M.R. Wertheimer. Nitrogen-rich plasma-polymer films for biomedical applications plasma process. Polym. 5 (2008) 44–57.

[17] P.-L. Girard-Lauriault, P. Desjardins, Wolfgang E.S. Unger, A. Lippitz, M.R. Wertheimer. Chemical characterisation of nitrogen-rich plasma-polymer films deposited in dielectric barrier discharges at atmospheric pressure plasma process. Polym. 5 (2008) 631–644.

[18] M.A. Kurbanov, I.S. Sultanakhmedova, É.A. Kerimov, Kh.S. Aliev, G.G. Aliev, and G.M. Geіdarov. Plasma crystallization of polymer–ferroelectric/piezoelectric ceramic composites and their piezoelectric properties. Physics of the Solid State, 51 (6) (2009) 1223–1230.

[19] Y. Kusano. Atmospheric pressure plasma processing for polymer adhesion: a review. The Journal of Adhesion, 90 (2014) 755–777.

|