ABSTRACT

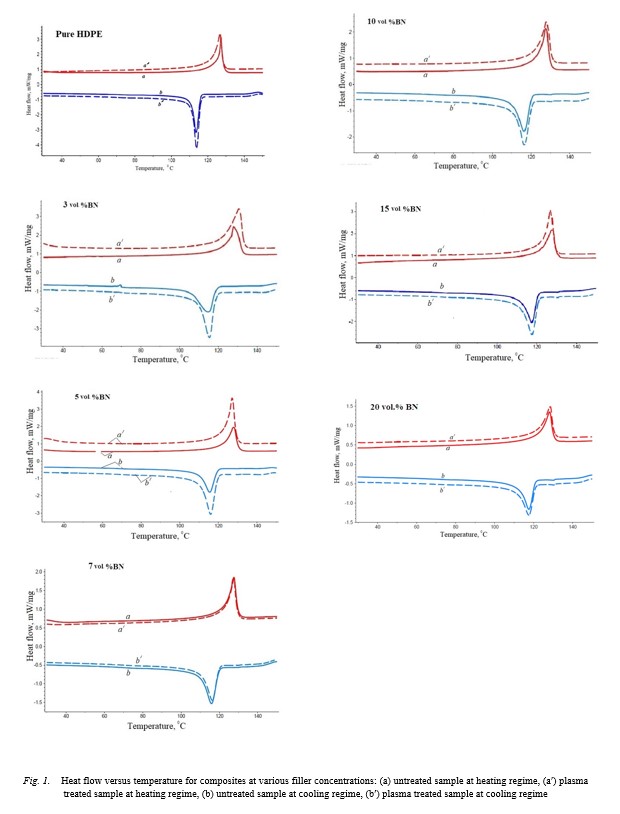

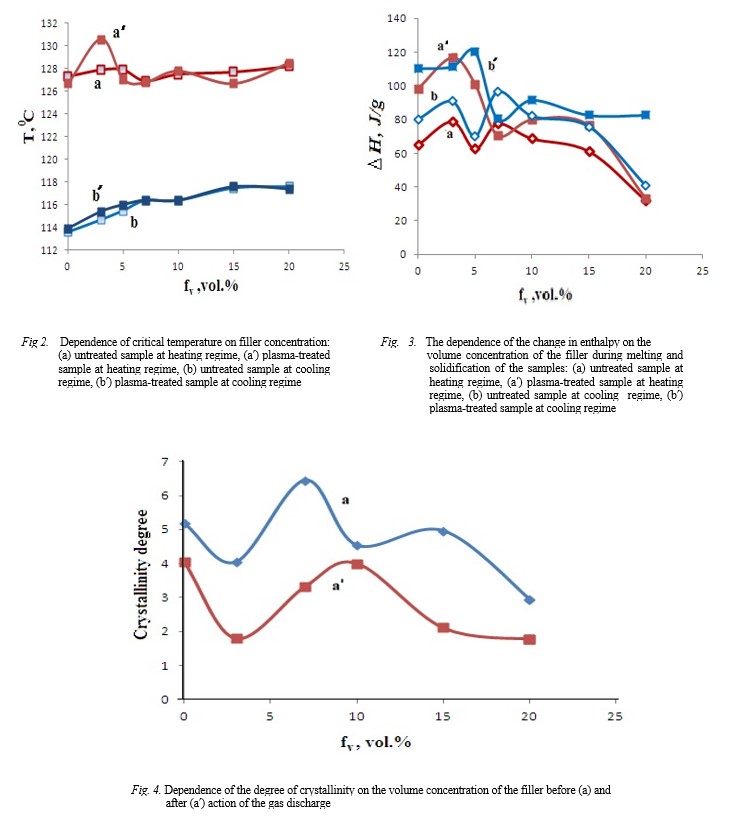

The effect of dielectric barrier discharge plasma before and after modification on thermo-physical properties of composites based on high density polyethylene and boron

nitride particles was studied. It has been established that with an increase in the volume fraction of the filler, the entropy and enthalpy decrease, except for 3vol.%

and 7 vol.%. The entropy and enthalpy increase after the plasma while the critical temperature almost does not change. The degree of crystallinity decreases after plasma

treatment.

Keywords: boron nitride, high density polyethylene, dielectric barrier discharge plasma; difference of enthalpy and entropy of composites, crystallinity.

PACS: 77.84.Lf, 77.65.-j

DOI:-

Received: 11.04.2023

AUTHORS & AFFILIATIONS

Institute of Physics, Ministry of Science and Education of Azerbaijan 131, H. Javid ave., Baku, АZ 1143

E-mail: tdibragimov @mail.ru

Graphics and Images

Fig.1 Fig.2-3-4

|

REFERENCIES

[1] J.M. Grace and L.J. Gerenser. Plasma treatment of polymers, J. Dispersion Sci. Technol. 24, 2003. 305-341.

[2] S. Guimond and M.R. Wertheimer. Surface degradation and hydrophobic recovery of polyolefins treated by air corona and nitrogen atmospheric pressure glow discharge, J. Appl. Polym. Sci. 94 (3), 2004. 1291-1303.

[3] M. Pascual, R. Sanchis, L. Sánchez, D. García, and R. Balart. Surface modification of low density polyethylene (LDPE) film using corona discharge plasma for technological applications, Journal of Adhesion Science and Technology 22, 2008. 1425–1442.

[4] M.R. Sanchis, V. Blanes, M. Blanes, D. Garcia, R. Balart. Surface modification of low density polyethylene (LDPE) film by low pressure O2 plasma treatment, European Polymer Journal 42 (7), 2006. 1558-1568.

[5] L. Paralı. The electret effects of crystallized polymer–ferropiezoelectric composite under electric discharge plasma, Journal of Electrostatics, 76, 2015. 89-94.

[6] I. Novak, M. Steviar, A. Popelka, I. Chodak, J. Mosnacek, M. Spırkova´, I. Janigova, A. Kleinova, J. Sedliacik, M. Slouf. Surface Modification of polyethylene by diffuse barrier discharge plasma. Polymer Engineering and Science. 2012. 1-8.

[7] F. Arefi-Khonsaria, M. Tatouliana, F. Bretagnola, O. Bouloussab, F. Rondelez. Processing of polymers by plasma technologies. Surface & Coatings Technology 200, 2005. 14 – 20.

[8] W. Kun, L. Jian, R. Chunsheng, W. Dezhen, W. Younian. Surface modification of polyethylene (PE) films using dielectric barrier discharge plasma at atmospheric pressure. Plasma Science and Technology, 10 (4), 2008. 433-437.

[9] L. Parali, M.A. Kurbanov, A.A. Bayramov, F.N. Tatardar, I.S. Ramazanova, G.X. Huseynova. Effects of electric discharge plasma treatment on the thermal conductivity of polymer–metal nitride/carbide composites. Journal of Electronic Materials 44 (11), 2015. 4322–4333.

[10] I. Novák, G.K. Elyashevichb, I. Chodák, A.S. Olifirenko, M. Števiar, M. Špírková, N. Saprykina, E. Vlasova, A. Kleinová. Polymer matrix of polyethylene porous films functionalized by electrical discharge plasma, European Polymer Journal 44, 2008. 2702–2707.

[11] M. Tahara, N.K. Cuong, Y. Nakashima. Improvement in adhesion of polyethylene by glow-discharge plasma. Surface and Coatings Technology, 174–175 (2003) 826-830.

[12] R. Morent, N. De Geyter, T. Jacobs, S. Van Vlierberghe, P. Dubruel, C. Leys, E. Schacht. Plasma-polymerization of HMDSO using an atmospheric Pressure dielectric barrier discharge plasma process. Polym. 6 (2009) 537–542.

[13] H. Biederman, D. Slavı́nská. Plasma polymer films and their future prospects. Surface and Coatings Technology. 125(1–3) (2000) 371-376.

[14] M.A. Kurbanov, V.A. Gol’dade, S.V. Zotov, I.S. Ramazanova, A.F. Nuraliev, F.F. Yakhyaev, U.V. Yusifova, B.G. Khudayarov. Generation of craze-formation centers in polymer films under the action of electric discharge plasma. Technical Physics 63 (2018) 965–969.

[15] A.I. Drachev, A.B. Gil’man. The synthesis of semiconducting polymers in a low-temperature plasma. Russian Journal of Physical Chemistry A, Focus on Chemistry 82 (2008) 1733–1741.

[16] A. Akay, O. Durukan, Y. Göncü, A. T. Seyhan, N. Ay. Hexagonal boron nitride filled polymer nanofibers producing and characterization via electrospinning technique. Akay et al. Usak University Journal of Material Sciences, 1 (2012) 35 – 41.

[17] L. Chen, H. Xu, Sh. He, Y Du. Thermal conductivity performance of polypropylene composites filled with polydopamine-functionalized hexagonal boron nitride. journal.pone. 0170523 January 20, 2017.1-16

[18] Y. Yang, Y. Peng, M. F. Saleem. Hexagonal boron nitride on III–V compounds: A Review of the Synthesis and Applications. Materials, 15, 2022. 4396

[19] F. Truica-Marasescu, M.R. Wertheimer. Nitrogen-rich plasma-polymer films for biomedical applications plasma process. Polym. 5 (2008) 44–57.

[20] P.-L. Girard-Lauriault, P. Desjardins, Wolfgang E.S.Unger, A.Lippitz, M.R. Wertheimer. Chemical characterisation of nitrogen-rich plasma-polymer films deposited in dielectric barrier discharges at atmospheric pressure plasma process. Polym. 5 (2008) 631–644.

[21] M.A. Kurbanov, I.S. Sultanakhmedova, É.A. Kerimov, Kh.S. Aliev, G.G. Aliev, and G.M. Geіdarov. Plasma crystallization of polymer–ferroelectric/piezoelectric ceramic composites and their piezoelectric properties. Physics of the Solid State, 51 (6) (2009) 1223–1230.

[22] Z.M. Cinan, T. Baskan, B. Erol, S. Mutlu. Thermal conductivity and phase change properties of boron nitride-lead oxide nanoparticles doped polymer nanocomposites. Research Squae. Turkey (2022)3-49.

[23] Y. Kusano. Atmospheric pressure plasma processing for polymer adhesion: a review. The Journal of Adhesion, 90 (2014) 755–777.

[24] P. Carminati, S. Jacques, F. Rebillat. Oxidation/corrosion of BN-based coatings, as future BN-based interphases for SiC/SiC composites. Journal of the European Ceramic Society, (2020) 03011733-1-24.

|