ABSTRACT

In the present work, thin films containing CuIn5Te8 with a thickness of 300 Å were obtained on various substrates by thermal evaporation of Cu2S and

In2S3

in a ratio of 1:5. The deposition rate of these layers was 15 Å/s, and the substrate temperature (Ts) varied from room temperature

to 500 K.The results of experiments on the formation of solid solutions containing CuIn5-xSnxS8 obtained on the basis of extreme lattices

of the superstructured phase as a result of the presence of the Sn element as an additive in this three-layer compound are presented. It has been established that the

lattice constants of solid solutions formed on the basis of the superstructured phase depend approximately linearly on the concentration of the additive (0.01≤х≤0.09 at.%).

Substitution

CuIn5-xSnxS8 reaches its maximum value (0.7Å) in the period of the cubic lattice, stoichiometric composition x=0.07 in solid

solutions.

Keywords: superstructure phase, superlattice, electron diffraction, triple compounds, single crystal layers, elementary core.

PACS: 61.50.ks

DOI:-

Received: 03.03.2023

AUTHORS & AFFILIATIONS

Institute of Physics Ministry of Science and Education Republic of Azerbaijan, 131 H.Javid ave, Baku, AZ-1143, Azerbaijan

E-mail: Uli200909@rambler.ru, cabirismailov@gmail.com

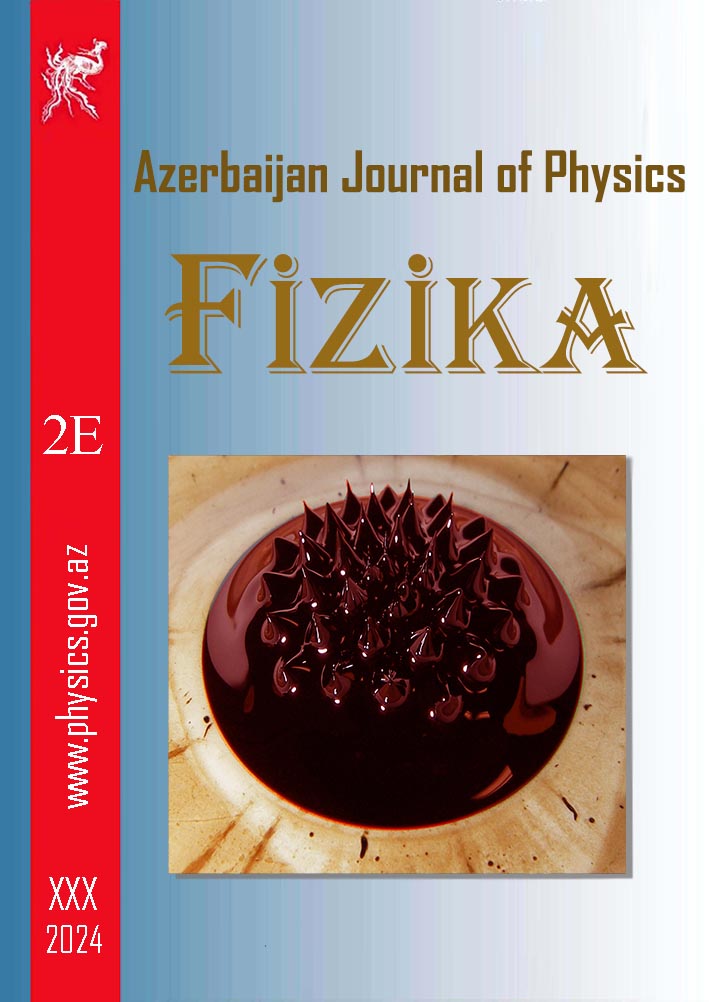

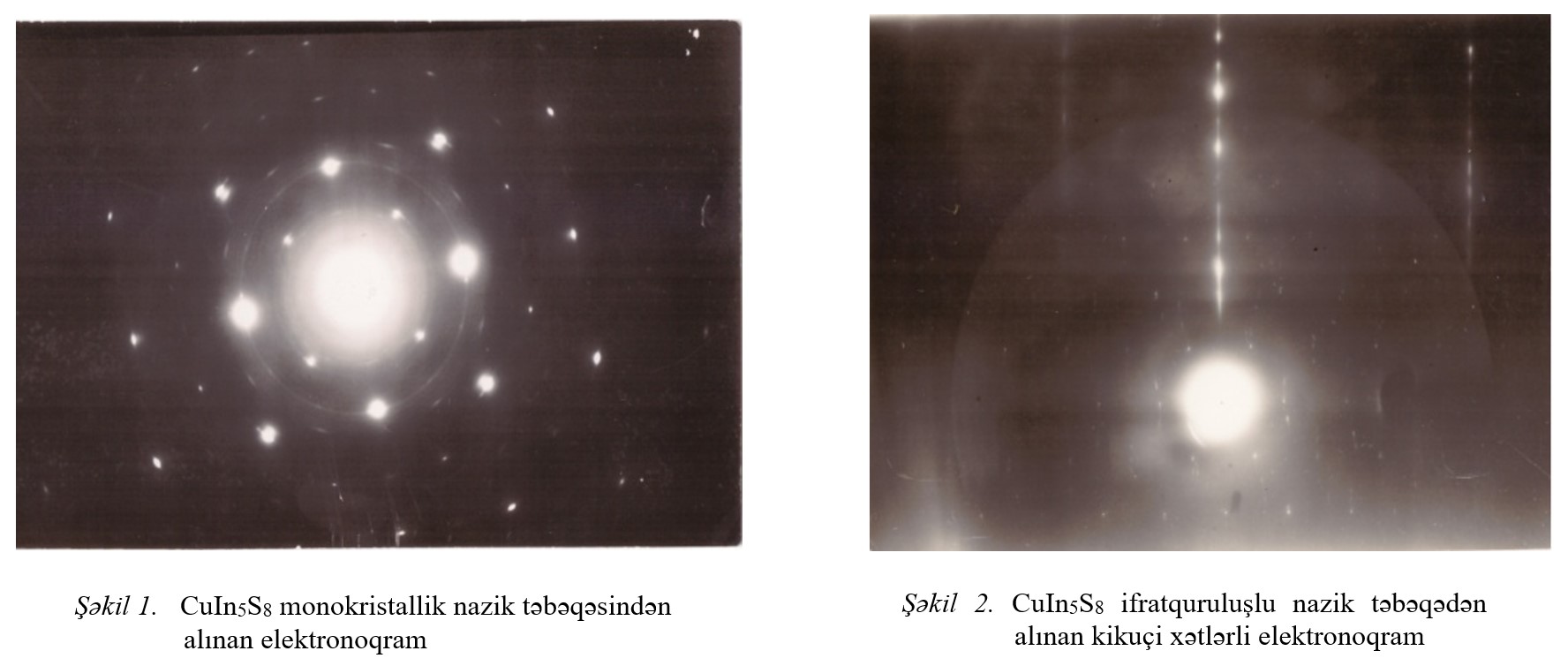

Graphics and Images

|

REFERENCIES

[1] S. Kitamura, S. Endo, T. Irie. Semiconducting properties of CuIn5Te8single crystals. I Electrical properties. Journal Phys.Chem.Solids., (46),1985, p. 881-885.

[2] Н.С. Орлова, И.В. Боднар, Е.А. Кудрицкая. Структура и физико-химические свойства CuIn5S8. Нерган. Материалы., 8(33), 1997, c.932-934.

[3] И.В. Боднарь, В.Ю. Рудь, Е.И. Теруков, А.М. Ковальчук. Фоточувствительные структуры на монокристаллах CuIn5Te8: создание и свойства. ФТП, 45(5), 2011, c.617-621.

[4] И.В. Боднарь, М.А. Жафар. Поверхностно-барьерные структуры основе монокристаллов твердогораствора (FeIn2S4)0,5·(CuIn5S8)0,5. Доклады БГУИР, 5(107), 2017, c.40-45.

[5] Г.Е. Дашдамирова, Э.Б. Аскеров, Д.И. Исмаилов. Фазообразование и кинетика кристаллизации аморфных пленок CuIn5S8. ФТП, 56(3), 2022, c.297-301.

|